Ich sehe, dass viele Käufer zögern, wenn sie sich für eine Münzmünzengröße entscheiden. Dieses Zögern beendet ihren Entwurfsprozess. Meine Erfahrung: Definieren Sie zuerst den Zweck der Münze und schließen Sie dann die Größe ab.

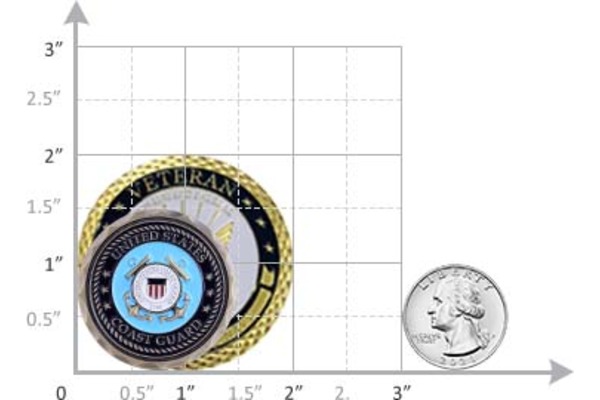

Die gemeinsame Herausforderung Münzengrößen reichen von etwa 1,75 Zoll und 2 Zoll. Diese Reichweite gleicht die Portabilität mit genügend Platz für detaillierte Grafiken aus. Wenn Sie Klarheit und Bequemlichkeit wünschen, trifft 2 Zoll oft den Sweet Spot.

Ich erinnere mich, dass ich zum ersten Mal eine 2-Zoll-Münze entworfen habe. Der Kunde bestand auf einer größeren Größe, erkannte jedoch später die Bedeutung der Portabilität. Jetzt möchte ich wichtige Größenfaktoren teilen, damit wir sie gemeinsam erforschen können.

Wie viel wiegt eine 2 -Zoll -Münzmünze?

Viele Käufer fragen nach dem Gewicht einer 2-Zoll-Herausforderung. Sie machen sich Sorgen um die Versandkosten und das Gesamtgefühl. Es ist eine der häufigsten Anfragen, die ich erhalte.

Eine 2-Zoll-Münzmünze wiegt in der Regel zwischen 25 und 35 Gramm, abhängig von Material und Dicke. Diese Sortiment bietet ein robustes, aber überschaubares Gewicht, das detaillierte Konstruktionsfläche mit kostengünstiger Versand ausbalanciert.

2-Zoll-Münzgewicht

Ich behandle oft die 2-Zoll-Münze als eine gute Balance zwischen Designraum und Portabilität. Bei 2 Zoll verfügt jede Seite über genügend Platz für aufwändige Designs, erhöhte Text oder komplizierte 3D -Elemente. Käufer, die eine starke visuelle Wirkung wünschen, wählen diese Größe häufig aus, da dies ein klares Marken- oder Gedenksymbole ermöglicht.

Ich arbeite mit vielen internationalen Kunden zusammen, die sich um Gewicht kümmern. Sie sorgen sich oft um Versandgebühren, insbesondere bei der Bestellung großer Mengen. Eine schwerere Münze kann die Kosten erhöhen, insbesondere wenn Sie eine schnelle Luftfracht benötigen. Meine Fabrik in China Exporte in die Vereinigten Staaten, Russland, Frankreich, das Vereinigte Königreich und andere globale Märkte. Logistische Ausgaben können sich schnell summieren, wenn jede Münze ein paar Gramm mehr als geplant wiegt.

Lassen Sie mich eine Geschichte über Mark Chen erzählen, einen Käufer aus Frankreich. Er ist ungefähr 50 Jahre alt und ist zuversichtlich, wenn er Geschäftsverhandlungen führt. Er konzentriert sich auf touristische Gedenkmünzen für malerische Stellen. Er will hochwertige Stücke zu wettbewerbsfähigen Preisen. Er kümmert sich auch um Versandkosten, weil er in großen Mengen für mehrere Standorte bestellt. Als wir zusammenarbeiteten, war er besorgt darüber, dass sich eine Münze größer als 2 Zoll für Gelegenheitstouristen zu schwer anfühlt. Er wollte auch die Gesamtversandgebühren im Budget behalten. Nach dem Vergleich verschiedener Proben erkannte er, dass 2-Zoll-Münzen mit jeweils etwa 30 Gramm einen Sweet Spot schlugen. Touristen schätzten das solide Gefühl und fanden es dennoch leicht zu tragen oder zu lagern.

Materialien und Gewichtsbereiche

Die Materialauswahl kann das Münzgewicht beeinflussen. Im Folgenden finden Sie eine einfache Tabelle, die ungefähre Dichten zeigt und wie sie das 2-Zoll-Münzgewicht beeinflussen:

| Material | Ca. Dichte (g/cm³) | Typisch 2" Münzgewicht (g) |

|---|---|---|

| Zinklegierung | 6.6–7.0 | 25–30 |

| Kupfer | 8.5–8,9 | 30–35 |

| Messing | 8.4–8,7 | 28–35 |

Normalerweise zeige ich Kunden wie diese Kunden, die Klarheit über Kosten wünschen. Verschiedene Plätze wie Gold oder Silber können etwas Gewicht hinzufügen. Dicke ist auch wichtig. Einige Menschen bestellen eine 3 mm Dicke für mehr Gewicht, während andere sich für etwa 2,5 mm entscheiden, um das Gewicht zu reduzieren. Mein Team kann die Dicke anpassen, wenn wir Ihren bevorzugten Bereich kennen.

Ausgleich zu Versandkosten und Kundenpräferenz

Der Versand kann ein wesentlicher Faktor für große Bestellungen werden. Ich habe vier Produktionslinien, die große Bände umgehen können. Jede zusätzliche Gramm pro Münze kann die gesamten Frachtkosten multiplizieren. Dieses Detail ist besonders wichtig für Geschäftsinhaber, die sich mit saisonalen Verkäufen wie Mark Chen befassen. Wenn Sendungen zu spät ankommen oder zu viel kosten, können Sie die Tourismuszeit mit hoher Handel verpassen.

Kunden fragen manchmal, ob sich eine leichtere Münze „billig“ anfühlt. Nach meiner Erfahrung hängt es von Ihrer Zielgruppe ab. Einige Unternehmenskäufer wollen eine Münze mit echtem Gewicht, um ein Prämiengefühl zu erzielen. Andere, wie Tourfirmen, wollen für Reisende etwas Leichteres. Ich erinnere meine Kunden daran, dass eine Differenz von 3 oder 4 Gramm pro Münze zu erheblichen Kostenänderungen für große Sendungen führen kann. Indem wir diese Punkte frühzeitig diskutieren, vermeiden wir Last-Minute-Überraschungen.

Produktionszeitpläne und Gewichtsanpassungen

Wenn Sie das Gewicht oder die Dicke mitten in der Projekt ändern, können sich die Produktionspläne möglicherweise verschieben. Alle neuen Spezifikationen können Formänderungen oder frische Designtests erfordern. Ich hatte ein Projekt mit Mark Chen, in dem er nach einer Probe um eine Dicke von 0,5 mm bat. Diese Optimierung zwang mich, die Form anzupassen. Die Zeitleiste verlängerte sich um zwei Wochen und die Materialkosten stiegen ein wenig. Ich rate den Kunden immer, Spezifikationen abzuschließen, bevor wir mit der Massenproduktion beginnen. Auf diese Weise können wir die beste Zeitleiste und Preise ohne plötzliche Änderungen sichern.

Massenbestellungen und konsequente Qualität

Wenn Sie eine große Bestellung aufgeben, ist ein konsistentes Gewicht und die Dicke sehr wichtig. Jede Challenge -Münze sollte gleich aussehen und sich gleich aussehen, oder Sie riskieren eine Inkonsistenz der Marke. Meine Fabrik investiert in die Qualitätskontrolle, so dass jede Münze eine Endinspektion durchführt. Wir wiegen zufällige Proben und messen die Dicke, um zu bestätigen, dass alles den vereinbarten Spezifikationen entspricht.

Ich habe mit großen Unternehmenskäufern zusammengearbeitet, die ISO -Zertifizierungen oder spezielle Sicherheitstests schätzen. Diese Verfahren können die Vorlaufzeit hinzufügen. Mark Chen wollte zum Beispiel bestimmte Zertifizierungen, um seine europäischen Käufer zu beruhigen. Wir haben diese Schritte in unseren Zeitplan aufgenommen. Klare Kommunikation über diese Anforderungen hilft mir, die Produktion genauer zu planen.

In welchen Formen kommen Münzen heraus?

Einige Leute gehen davon aus, dass alle Herausforderungsmünzen rund sind. Aber auch Münzen kommen in quadratischen, schild oder benutzerdefinierten Formen. Die Formauswahl kann die Markenwerte verstärken oder das einzigartige Thema einer Veranstaltung hervorheben.

Herausforderungsmünzen erscheinen in einer Vielzahl von Formen: rund, quadratisch, oval, schild oder sogar verspielte kundenspezifische Silhouetten. Unternehmen oder Veranstaltungsplaner wählen Formen aus, die mit ihrer Botschaft übereinstimmen, und erstellen unverwechselbare Designs, die mit dem Zielgruppen in Anspruch nehmen.

Münzformen

Die Formauswahl kann die Produktionskosten, die Komplexität der Form und die visuelle Anziehungskraft beeinflussen. Runde Münzen sind klassisch und kostengünstig, da die Schimmelpilze einfacher ist. Aber ich habe gesehen, dass kreative Formen eine stärkere Markenerkennung oder den Gedenkwert erzeugen. Im Laufe der Jahre habe ich Kunden dabei geholfen, schildförmige Münzen für Sportveranstaltungen, rätselhafte Münzen für Teambuilding-Funktionen und sogar sternenförmige Münzen für patriotische Feierlichkeiten zu gestalten.

Gemeinsame Formen und ihre Verwendung

- Runden: Standard für die meisten Herausforderungsmünzen. Die Käufer wählen sie für einfachere Schimmelpilze und eine breite Konstruktionsfläche.

- Quadratisch/rechteckig: Ideal zum Hervorheben von Text oder malerischen Silhouetten. Museen und Tourismusbretter bevorzugen manchmal rechteckige Formen, um Sehenswürdigkeiten zu präsentieren.

- Schild: Beliebt bei Strafverfolgungs-, Militär- oder Sportveranstaltungen, um Schutz, Ehre oder Sieg zu symbolisieren.

- Oval: Eine schlanke Alternative zu runden Formen. Oft für längliche Designs wie City Skylines verwendet.

- Custom oder "Cut-to-Form": Ermöglicht einzigartige Umrisse wie Embleme, Tierfiguren oder Logos. Diese Option kostet mehr, weil sie spezielle Schimmelpilze erfordert.

Ich finde, dass Formentscheidungen oft von Event -Themen oder Organisationsbranding abhängen. Eine Reisefirma möchte möglicherweise die Form ihres nationalen Denkmals. Ein Museum könnte eine Münzform anfordern, die wie ein Schlüsselartefakt geformt ist. Vor kurzem forderte ein Unternehmenskäufer eine Form an, die den abgewinkelten Kanten ihres Logos ähnelte. Diese Münze weckte viel Interesse an Messen.

Schimmelkomplexität und Kosten

Komplexe Formen erfordern normalerweise detailliertere Formgestaltung. Die Form muss feine Winkel, Ecken oder Ausschnitte ausmachen. Unser CNC -Prozess in der Fabrik ermöglicht präzise Werkzeugpfade, die Kosten sind jedoch höher als eine grundlegende runde Form. Ich empfehle Kunden, die Kosten einer benutzerdefinierten Form mit den potenziellen Marketingvorteilen zu vergleichen. Eine unverwechselbare Form kann sich in Social -Media -Posts oder Event -Werbegeschenken auszeichnen und möglicherweise die Sichtbarkeit der Marke erhöhen.

Wenn Sie die Schimmelpilzkosten senken möchten, können wir manchmal vorhandene Formen in unserer Bibliothek anpassen. Zum Beispiel habe ich eine Standardschildform, die für leicht unterschiedliche Abmessungen eingestellt werden kann. Dieser Ansatz kann billiger sein als eine brandneue Schildform von Grund auf neu. Mark Chen fragte einmal, ob ich eine Form habe, die ein berühmtes französisches Wahrzeichen ahmte. Wir hatten keine genaue Übereinstimmung, also haben wir uns mit einer neuen Form ausgesprochen. Trotzdem haben wir eine angemessene Schimmelgebühr ausgehandelt, um zu seinem Budget zu passen.

Kombinieren Sie Form mit Branding

Ich sage Kunden oft, dass Form Teil einer allgemeinen Markenstrategie ist. Ihre Münzform kann Ihre Unternehmensidentität oder das Thema einer Veranstaltung widerspiegeln. Wenn Sie beispielsweise ein Sicherheitsunternehmen betreiben, übereinstimmt eine Schildform mit Sicherheit und Sicherheit. Wenn Sie sich auf die Natur konzentrieren, sollten Sie Blattrininen oder Berg Silhouetten in Betracht ziehen. Visuelle Konsistenz hilft den Menschen, sich an Ihre Marke zu erinnern.

Viele Käufer aus den Vereinigten Staaten wie Shield oder Starformen, möglicherweise aufgrund kultureller Referenzen. In Russland habe ich Interesse an geometrischen Umrissen oder robusten hexagonalen Formen gesehen. Europäische Länder können stark variieren, aber viele bevorzugen traditionelle Kreise, wenn die Münze für ein formelles Museum oder ein Gedenkveranstalter bestimmt ist. Mark Chen, obwohl er in Frankreich ansässig ist, wollte etwas, das sich für seinen Touristenmarkt frisch und faszinierend anfühlte. Er betrachtete eine Münzform wie ein berühmtes Denkmal, wählte aber schließlich eine runde Form mit einem erhöhten, geprägten Bild des Denkmals. Manchmal kann eine runde Münze mit 3D -Erleichterung diesen Sweet Spot zwischen Tradition und Innovation erreichen.

Auswirkungen auf die Vorlaufzeiten

Form kann auch die Bleizeiten beeinflussen. Eine runde Münze ist unkompliziert. Wenn Sie jedoch eine komplexe benutzerdefinierte Form anfordern, benötigt mein Produktionsteam zusätzliche Zeit, um die CNC -Maschine zu programmieren. Wenn Sie 3D -Details hinzufügen, müssen wir die Form weiter verfeinern. Sobald die Form fertig ist, führen wir Testangriffe durch, um die Ausrichtung und Details zu bestätigen. Jeder Test kann zu geringfügigen Überarbeitungen führen. Wenn Sie eine enge Veranstaltungsfrist haben, lassen Sie es mich so schnell wie möglich wissen. Wir können beraten, ob eine einfachere Form Ihre Zeitleiste erfüllen würde. Das Stürzen einer komplexen Form kann zu weniger idealen Ergebnissen oder höheren Defektraten führen.

Praktische Überlegungen für Ereignisse

Wenn Ihre Veranstaltung viele Teilnehmer umfasst - wie ein Marathon oder ein großes Unternehmenssammlung -, können Sie Formen, die leicht zu stapeln oder zu packen sind. Gelegene Formen erfordern möglicherweise spezielle Verpackungen, die die Kosten steigern. Ich hatte einen Kunden, der auf einem sehr ausgefeilten Ausschnittsdesign bestand. Es sah toll aus, aber der Versand wurde kompliziert, da jede Münze zusätzliche Polsterung benötigte, um Kratzer oder Biegen zu vermeiden. Wenn Sie bis zu Tausende von Münzen skalieren, kann dieses Verpackungsdetail Ihr Budget belasten.

Ich schlage immer vor, die Vor- und Nachteile von benutzerdefinierten Formen abzuwägen. Eine kreative Form kann Aufmerksamkeit auf sich ziehen, aber sie kann mit höheren Schimmelpilzgebühren, längeren Produktionszeitplänen und schwierigeren Versand geliefert werden. Runde oder leicht maßgeschneiderte Formen können weiterhin visuell auffällig sein, wenn Sie vielleichte Relief- oder unterschiedliche Farbfüllungen verwenden. Es hängt alles von Ihrer Markenidentität, Ihrer Ereignisziele und Ihrem Budget ab.

Abschluss

Herausforderungsmünze Größe und Form können die Kosten, den Versand und die allgemeine Attraktivität beeinflussen. Ich möchte immer Ihr Markenimage mit praktischen Produktionsdetails anpassen. Auf diese Weise sieht jede Münze gut aus, fühlt sich richtig an und schickt pünktlich.