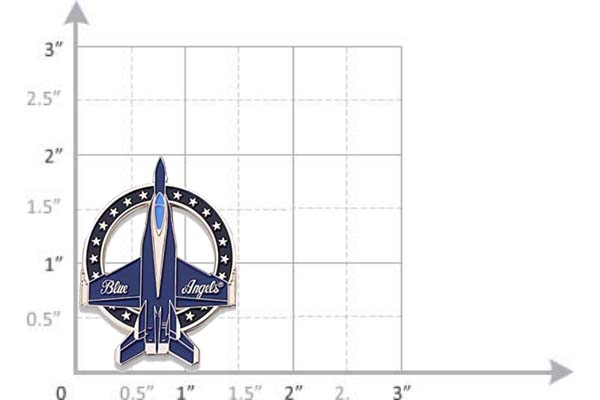

I see confusion about standard challenge coin sizes. People worry about design fit. I focus on balancing practicality and style.

Common challenge coin diameters range from 1.5 to 2.5 inches, though some go bigger. I prefer around 2 inches for a practical balance of weight, detail visibility, and comfort in handling.

I recall Mark Chen, a buyer from France, who struggled choosing the right coin size for his scenic spot souvenir line. He asked me for advice, and that moment made me refine my sizing guidelines.

What is the average height of a challenge coin?

I often hear buyers wonder if there is a standard height or thickness for challenge coins. My answer involves both design considerations and practical usage.

The average thickness is around 3 mm, while the diameter often measures 1.75 to 2 inches. I believe these proportions offer a comfortable weight and highlight essential details, without feeling too bulky.

I want to examine how coin size and thickness shape the final product. I work at INIMAKER in China, where I run a B2B wholesale operation. I have four production lines, and I serve clients across the United States, Russia, France, the United Kingdom, and other European and American countries. I focus on deep customization for challenge coins, medals, and badges. My customers often ask how size impacts the look and feel of a coin. I believe the answer lies in careful consideration of diameter, thickness, and design objectives.

The Importance of Diameter

I notice that a coin’s diameter directly affects how people see the artwork. A 2-inch coin has enough space for logos, text, and intricate details. I have seen Mark Chen choose a 2-inch diameter because it fits scenic images well. He sells these coins in offline stores near famous landmarks. If I go larger than 2.5 inches, shipping costs and metal usage rise. This can affect profit margins, especially for bulk orders.

Thickness as a Factor

Thickness can boost a coin’s perceived value. I produce coins that range from 2 mm to 4 mm in thickness, although 3 mm is my usual recommendation. Thicker coins feel heavier and sturdier. That sense of weight often impresses corporate buyers or museums, like those in my partner network. However, thicker coins may lead to longer production times. That is because detailed embossing and polishing require careful work.

Here is a table that shows my typical thickness recommendations:

| Thickness (mm) | Suggested Diameter Range (in) | 注意事項 |

|---|---|---|

| 2 | 1.5–1.75 | Lightweight, lower cost |

| 3 | 1.75–2.0 | Standard balance, popular choice |

| 4 | 2.0–2.5 | Heavier feel, premium impression |

I used this table when advising Mark Chen. He wanted premium coins for tourists. We settled on 3 mm thickness and a 2-inch diameter. That size felt comfortable in people’s hands and made the scenic engraving stand out.

Weight and Shipping Considerations

I work with clients who are sensitive to shipping costs, especially those ordering large volumes. Small differences in coin size can influence total shipping weight. Bulk orders to France, Russia, or the United States can become costly if the coins exceed standard weight thresholds. I suggest considering the shipping impact before finalizing an oversized design. Balancing the thickness and diameter often saves time and money.

How do color, plating, and edge styles elevate challenge coin design?

I sometimes encounter other questions about customizing challenge coins. These questions involve color options, edge styles, and plating choices. I want to address a few of them here.

I often recommend using sturdy metals like zinc alloy or brass, combined with bold plating finishes. I find that these materials provide a stable base for intricate custom designs and logos.

I have learned that personalization matters greatly to corporate buyers and collectors. Most of my customers look for designs that reflect their brand identity or event theme. Sporting goods buyers might add bright enamel fills, while coin dealers often prefer antique finishes. Either way, I notice that they all share one key concern: how the final product will appear in hand.

Color and Plating Choices

I usually offer gold, silver, bronze, or nickel plating. Each plating style changes the overall impression of the coin. Bright gold plating, for instance, draws attention at exhibitions. Brushed nickel plating creates a subtle yet refined appearance. When I supply to museums, they request aged bronze effects. That look pairs well with historical displays.

エッジオプション

I produce plain, rope-cut, or diamond-cut edges. Plain edges are straightforward to manufacture and keep costs down. Rope-cut edges add a textured grip that feels traditional. Diamond-cut edges sparkle under light. If the coin’s diameter is large, edges stand out more. I personally like the diamond-cut style on 2-inch coins. That detail makes the border pop.

Mark Chen’s Case

Mark Chen once asked me about a rope-cut edge on a 2-inch coin. He hoped that tourists would appreciate a tactile finish. I offered him rope-cut combined with raised enamel details. It took extra work, but the final product looked elegant. The coin sold well during the summer tourist season in France. That experience showed me how small design tweaks can make a difference.

結論

I believe a thoughtful approach to size, thickness, and design details leads to a memorable challenge coin.