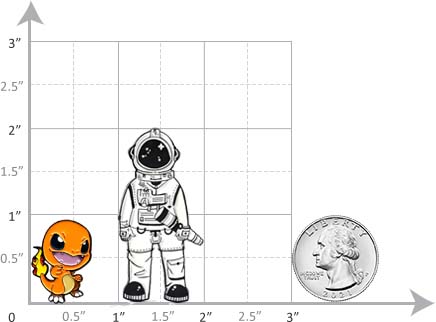

I see people struggle with pin sizes. They worry about choosing the wrong dimensions. I want to ease that worry with clear steps.

Small pins (0.5–0.75 inch) work well for discreet branding, while a 1-inch size covers most professional and everyday needs. Larger pins (1.5 inches or more) showcase intricate details or logos. Trading pins often measure 1.5–3 inches for visual impact and collector appeal.

I measure a pin by looking at its width and height. I also check how much space any design elements take up. Pin size is important because it affects visual impact, usability, and cost. When pins are too small, the details can get lost. When pins are too large, they might weigh too much or become awkward. In my own projects at INIMAKER, I like to consider several factors before finalizing a design. I think about the event theme and the audience who will wear or collect these pins. My customers usually want their logos or text to stand out. So I balance clarity and aesthetics.

I learned to look at thickness, too. Thicker pins might stand out more, but they can get heavy. In my B2B business, I have discovered that many corporate buyers prefer pins in the 1-inch to 1.25-inch range because these pins feel visible but not oversized. I try to help them see how each element affects the final size. For example, a simple text design can be smaller, but a complex image might need extra space. I want my customers to get the right fit for their markets. Whether they are large corporations, travel companies, or museums, they all value precision. They also care about cost. Larger pins cost more in material, shipping, and packaging. That is why I keep pin sizes practical.

I remember making my first batch of oversized pins, and they hardly sold. I want to share my lessons, so you can avoid the same fate.

What is the perfect size of pins?

Some people want a pin that looks bold. Others prefer something discreet. I will show how to pick the best size.

A perfect pin size balances visibility, detail clarity, and comfort. Most buyers pick between 1 inch and 1.5 inches for general use.

I have worked with many clients who ask, “Should my pins be smaller or bigger?” I answer with caution. I say the perfect size depends on purpose, design complexity, and personal taste. It also depends on where the pins will be displayed or worn. Let me break it down further:

Purpose and Occasion

A corporate event pin might need to be subtle. A sports team might prefer a more eye-catching design. A museum gift shop might need pins that show intricate art, so they might go a bit bigger.

Ontwerpcomplexiteit

If there is text or a logo, it must be legible. That often sets a minimum size. If there is lots of detail, I prefer pins at least 1.25 inches wide. This gives enough space to show lines and color without crowding.

Comfort and Practicality

A pin that is too large might feel clunky on clothing. It could pull on fabric or snag. A smaller pin is easier to wear but might not be noticed. I ask customers to consider daily usage. Will people wear them on hats, lanyards, or jackets?

| Pin Size Range | Usual Use Case | PROS | Nadelen |

|---|---|---|---|

| Under 1 inch | Minimalist designs or subtle branding | Lightweight, discreet | Harder to read fine details |

| 1 inch - 1.25in | Common for corporate events and brand promotions | Good balance of visibility | Might still limit very complex artwork |

| 1.25in - 1.5in | Detailed logos, commemorative designs, travel souvenirs | Clear details, noticeable | Can feel bulky for some wearers |

| Over 1.5 inches | Statement pieces or collector’s editions | Bold visual presence | Heavier, higher cost, potentially awkward |

Sometimes I work with a buyer named Mark Chen, from France. He is 50, and he runs a company that sells tourist commemorative coins and pins. He told me he prefers 1.25-inch pins for his stores near tourist sites. He wants visitors to see the pin’s scenic detail, but also keep it easy to wear. He trusts me because I am from INIMAKER in China, and my factory can produce custom sizes. I do wholesale for him, so we take advantage of the scale. That approach keeps the price attractive while ensuring quality. Because Mark pays attention to cost, I must plan the raw materials wisely. If we overshoot the size, shipping costs rise. If we go too small, the design might lose clarity. So I rely on my experience, my production lines, and my knowledge of export rules. This helps me suggest the perfect size.

When I set up a pin order, I always ask the customer about usage. Will they be worn daily, or are they for special events? Will they be used as souvenirs, or collected by serious pin enthusiasts? Each answer guides me to a recommended size. I focus on practicality. I also think about future possibilities. If the pins are too big, they might not fit well into standard packaging. If they are too small, people may not appreciate the details. I remind clients that a perfect pin size is a blend of design, comfort, and cost-effectiveness.

How do you measure a pin size?

I measure a pin by its height and width. That is the best way to gauge overall dimensions.

To measure a pin size accurately, check its widest points. This includes any protrusions or cutouts. Use a ruler or digital caliper for precision.

I start by laying the pin flat on a smooth surface. I then look at the highest and widest parts. If the pin has a non-standard shape, like a star or an irregular outline, I make sure to include those outer tips. I am in China, so I often work with both metric and imperial units, but most of my international customers use inches. Some prefer millimeters for smaller pins, especially if they want a near-exact size.

Steps for Accurate Measurement

- Lay the pin flat.

- Align the ruler or caliper with the widest horizontal points.

- Write down that measurement.

- Align the ruler with the tallest vertical points.

- Record that figure as well.

- Combine these results for a final size, for example, “1.2 inches wide x 1 inch high.”

I learned this method after shipping a batch of pins to a corporate buyer in the United States. The buyer thought the pins were a bit smaller than promised. I realized we measured only the main rectangle. We forgot about the small protruding sections. That experience taught me to measure carefully, so I now use digital calipers. Digital calipers reduce guesswork and help me reassure my customers that the final product matches the design files.

I also pay attention to thickness. Some customers want a thin pin for easy wear. Others, like Mark Chen, want a sturdier coin-like finish. They see pins as souvenirs, so they want them thick enough to feel solid in hand. When I set up production, I measure thickness with the same caliper. I do not want any surprises when the final product arrives.

Why Thickness Matters

- Duurzaamheid: Thicker pins can handle impact better.

- Gewicht: Extra material adds weight. Some customers prefer lighter pins.

- Kosten: Thicker pins need more raw material. That increases expense.

| Measurement | Importance | Opmerkingen |

|---|---|---|

| Width | Defines horizontal space the pin occupies | Crucial for text or logo spread |

| Height | Determines overall vertical height | Affects how large the design appears |

| Dikte | Impacts weight, durability, and perceived value | Heavier pins can feel premium or too clunky |

I share this measurement process with my potential clients at exhibitions. I also write about it on my website: www.inimaker.com. I focus on B2B inquiries, so I have to be thorough. Buyers expect clarity, especially for large wholesale orders. Measuring a pin size seems simple, but it is easy to overlook small details. If a customer needs a quick reference, I send them a short video. I walk them through each step, showing the ruler or caliper in action. By doing that, we avoid confusion and ensure a smoother transaction.

I want to explain how my business approach helps me guide customers toward the right pin size. I work at INIMAKER, and I have four production lines in my factory. I only do wholesale, so I focus on large batches. That means each size decision must be correct. I cannot risk producing thousands of pins that do not meet the client’s expectations. Here is how I handle that:

My Pin Sizing Consultation Process

I always start with a discussion. I learn about the client’s target audience and brand image. Sometimes that includes large corporate buyers who want a set of branded pins. Other times, it is sporting goods buyers who want pins for marathons or tournaments. I figure out whether the pins will be used for staff identification, fan souvenirs, or brand marketing. Once I know the function, I can suggest a suitable size range.

Adjusting for Export and Logistics

I export to the United States, Russia, France, the United Kingdom, and other European and American countries. Each market might have different preferences. For example, Russian buyers sometimes prefer slightly larger pins for their winter coats, so they stand out on thick fabric. My French clients like Mark Chen value detail, so they aim for that 1.25-inch sweet spot. Shipping is another factor. Larger or heavier pins mean bigger costs. I do not want my clients to face unexpected shipping fees, so I always factor in size and weight when quoting.

Payment Terms and Communication

Some clients worry about payments, especially if they have had problems with delayed shipments. I keep communication open, and I provide updates at each step. I also offer multiple payment methods. I learned that trust is essential. If the buyer is confident about the pin size and the production timeline, they are less nervous. I also offer certifications for my materials to show that everything meets safety standards. This process helps me stand out in the B2B space.

Meeting Aesthetic and Quality Needs

Many customers, especially those who run museums or coin shops, want more intricate designs. They often request bigger pin sizes. But I know that too big can increase the chance of missing the sales season if production or shipping runs late. I remind them that a more moderate size is faster to produce, and sometimes that helps them meet deadlines. I also handle the finishing touches, from plating choices to color matching. These details can influence perceived size. A pin with a bright enamel color might appear bigger to the human eye than a pin with a less vibrant design. So I keep that in mind.

Communication Pitfalls with Suppliers

I have heard from buyers who say they struggled to get a consistent size from other factories. That leads to shipping delays or missed seasons. I try to solve this by showing them actual prototypes or 3D renders. This is crucial when finalizing the measurement. I want them to feel comfortable that what I measure is what they get. In the past, I have seen other sales representatives promise a certain dimension but fail to account for the protruding shape of custom elements. By clarifying measurements, I avoid that pitfall.

Example: Pin Size for a Travel Company

Imagine a travel company that wants to create a special pin for a new scenic route. They need something slightly bigger to display a tiny map detail. I might suggest 1.5 inches. We discuss thickness. They want it sturdy because travelers might keep it as a keepsake. So we go for a thicker base metal. That might raise the cost. But the travel company sees it as a brand investment, so they are fine with that. If they insisted on 2 inches, I would caution them that shipping rates rise quickly. I would also mention that it might overwhelm the user’s clothing or bag. Usually, they trust my experience, and we settle on a balanced size.

Personal Story: My Early Mistakes

Early in my career, I assumed that bigger pins always meant more impact. I sent a shipment of pins that were over 2 inches wide. The buyer complained that staff did not want to wear them. They were heavy, and they felt like a burden. That taught me to check real-world usability. Now, I focus on both design and practicality.

Engaging with Potential Customers

At exhibitions, I share a small kit that shows different pin sizes. Buyers can pick them up, feel the weight, and compare details. This is especially helpful for new clients who do not have reference points. That personal touch builds trust. I also offer digital mockups for those who cannot attend exhibitions. These mockups show the same design in multiple sizes, side by side. The buyer can then pick their favorite. I then confirm the final dimension with a measurement in writing. This step ensures we align on the perfect size.

Conclusie

A pin size influences design, comfort, and costs. I always measure carefully to guide my clients toward the right fit.